The New Identity Card in the Tire Industry: Making the Whole Process Better, from Making Tires to Recycling Them. Using Radio Frequency Identification (RFID) technology in the tire business has made things easier and more efficient for manufacturers, suppliers, service shops, and people who recycle tires. The following is a thorough look at how RFID is used in the tire business:

Put RFID tags on your new tires:Management of tire information: By putting RFID tags on tires, manufacturers can store a lot of information about them, like the type, size, date of production, batch number, and so on. Keeping track of supplies, recalls, and customer service all depend on these pieces of information.

Maintenance Plan Optimization: RFID readers let repair shops quickly find detailed information about tires, which helps them make better maintenance plans. Mechanics can also quickly check to see if tires are right for certain vehicles, which improves the level of service.

Recall management: If a batch of tires has problems, RFID systems let makers quickly find and recall the bad tires, which lowers the risk of accidents.

Keeping track of inventory and giving recycle certificates

Control of inventory: RFID systems can make control of tire inventory a lot more accurate. RFID tags let suppliers and makers keep track of their inventory in real time and improve the logistics and order processing processes.

Reusing proof: RFID tags make the process of reusing tires more clear and easy to track. Tires can be easily tracked back to their source, the date they were thrown away, and how they were thrown away. This gives car owners and government offices proof that the tires were recycled.

Environmental benefits: Manufacturers and recyclers can offer recycling incentives to encourage people to use tires in a way that is good for the environment by keeping track of the number of tires that are recycled using RFID systems.

RFID during the making process

Production process optimization: RFID tags help manufacturers keep track of the state of raw materials, half-finished goods, and finished goods in real time, which improves the efficiency of the production process. RFID systems can also make sure that the right products and methods are used during the manufacturing process.

Watching over quality: The RFID system can keep track of all the steps that go into making a tire, like what materials were used, how long it took to make, the results of any quality checks that were done, and so on. With this knowledge, manufacturers can spot possible quality problems early on and take steps to fix them.

Factory management: Putting RFID tags on vehicles, tools, and other things in the factory can help manufacturers see how the factory is running in real time and make factory management more efficient.

I would say that the use of RFID technology in the tire business has completely changed everything about it. RFID technology is a big part of making the tire business more efficient, accurate, and able to track things from production to sales to maintenance to recycling. With technology always getting better, RFID will be used in more areas and in more depth in the tire business.

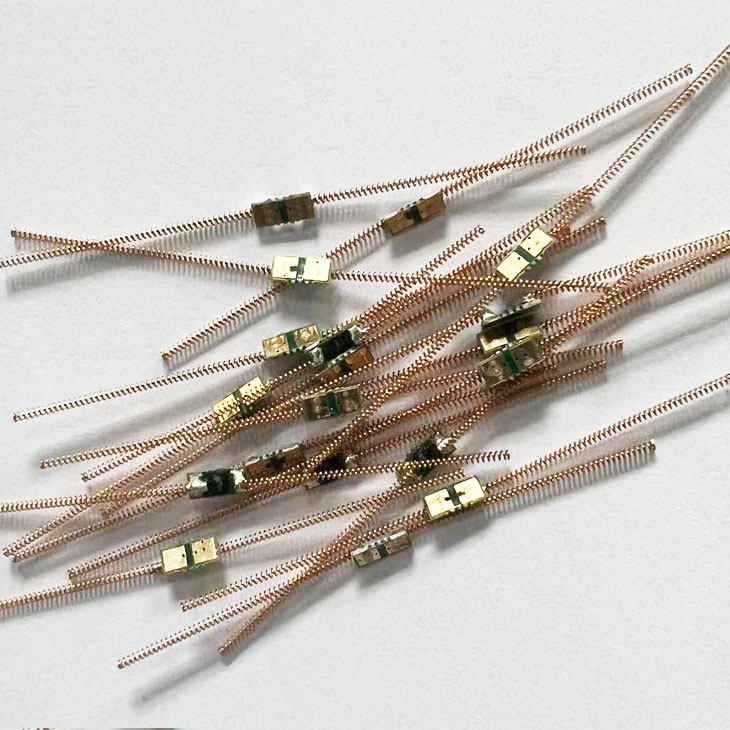

Here are two tire tags. Please click to learn more details,