The feature of plastic HF High Temperature RFID Screw Tag

-

Operating Frequency: 13.56 MHz

-

Reading Distance: <5cm (It depends on size or reader power, frequency)

-

Chip Type: ICODE series, NXP series.

-

Size: M8

-

IC write endurance: 100,000

-

Material: PA

-

Data retention: 10years

-

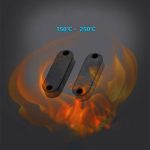

Operating Temp: -35℃ to +100℃

How smallest rfid screw tags can be?

Normally, rfid screw tags with a diameter exceeding 8mm. Due to the small screw head,

the antenna is very small. As a result, the reading distance is very poor. So it’s not recommended.

Plastic rfid screw tags can do UHF or HF frequency, chip option as below,

HF(13.56MHz):FM11RF08、M1 S50、M1 S70、Ultralight、I-CODE2、TI2048、SRI512 etc

UHF(860MHz-960MHz):UCODE GEN2、ALIEN H3、IMPINJ M4 etc

Rfid screw tags can choose plastic or metal, as below is metal rfid screw picture.

What kind of occasions are recommended to use rfid screw tags?

Here are some occasions for your reference,

1. Need to replace screws frequently: For devices that require frequent maintenance and screw replacement, RFID plastic screw tags are used to track and see the maintenance history and replacement records of screws. This boost the equipment’s service life and reliability. Reduce malfunctions caused by loose or damaged screws.

2.Inventory management: If you have a lot of different kinds of screws, you can use RFID scew tags on the package that they come in to keep track of how many are in stock and where they are located during the sales and inventory management processes. And to avoid inventory backlog and out of stock phenomena.

3.When security is very important, like in flight, medical devices, and other places, RFID screw tags can be used to reliably track and verify items. Through RFID technology, rapid identification and verification of key components such as screws can be achieved, ensuring the safety and integrity of the equipment.

As below when you choose rfid screw tags maybe need to consider,

Reading distance limitation: This must be taken into account when choosing application scenarios because high-frequency RFID tags have a relatively small reading distance. If long-distance identification is required, ultra-high frequency (UHF) RFID tags may need to be used.

RFID Screw Tag size: Due to the limitation of reading distance, the smaller the size, the shorter the reading distance. So the M8 size RFID screw tag is already considered a very small size, but in some extreme cases, a smaller size is needed, and a new solution maybe need to use other tags.

Material selection: Plastic RFID screw tags are suitable for most environments, but in extreme high temperature or highly corrosive environments, it may be necessary to consider using metal or other special materials for RFID tags.

To sum up, plastic high-frequency and high-temperature RFID screw tags offer a variety of applications and special benefits. They are crucial in inventory control, equipment management, and high-security application.