The application background of Metal Rfid Tags For Oil And Gas Asset Tracking

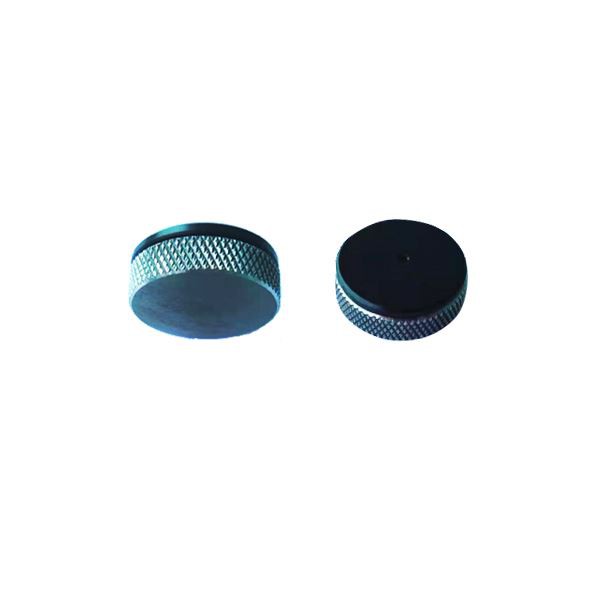

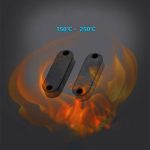

Because of the heat generated during drilling, many RFID tags can be disabled: they come loose or become trapped in thick mud and cannot be read. In this reason, our company specializes in the development of a special oil drill pipe RFID tag, circular design, all stainless steel shell, when in the swirling flow, pressure, heat, abrasion and a variety of chemicals in the oil well environment, the metal rfid tag still has a strong adhesion to the drill pipe. The embedded RFID tags for oil drilling developed by our company are more durable and robust than similar tags on the market and can withstand high and low temperatures. They are specifically designed to be embedded in the hole of the drill pipe joint to track each individual pipe.