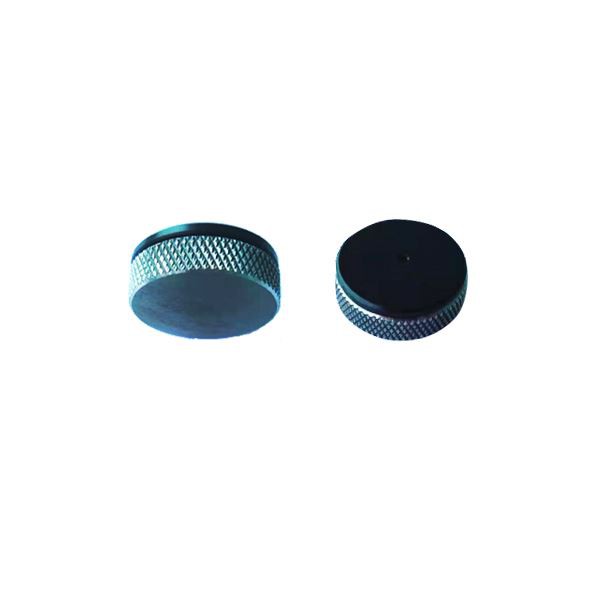

Want to handle mold more simply and effectively? RFID screw tags come to help, making every link clearly visible!

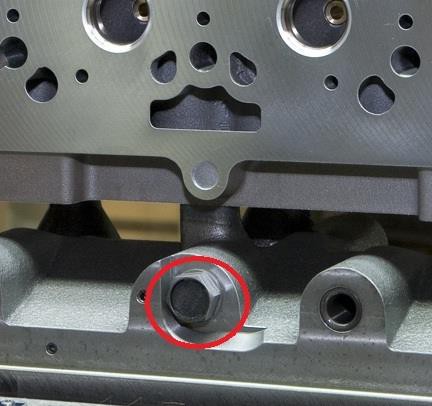

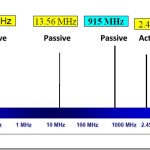

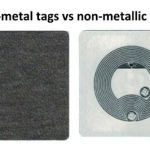

Taking UHF as an example, install a metal RFID scew tag on each mold and write the EPC code. Each EPC code is equivalent to the mold’s identification code.

1. Match the mold ID code with the corresponding mold information in the system, such as mold number, production date, mold type, processing material, maintenance time and other data.

2.Use the RFID reader to read the metal RFID scew tag as you enter and exit the warehouse, and the data will automatically be updated with the latest information.

3. In addition, you can know the mold location by scanning quickly. Or you can check background database to know the each mold maintenance status and maintenance time.